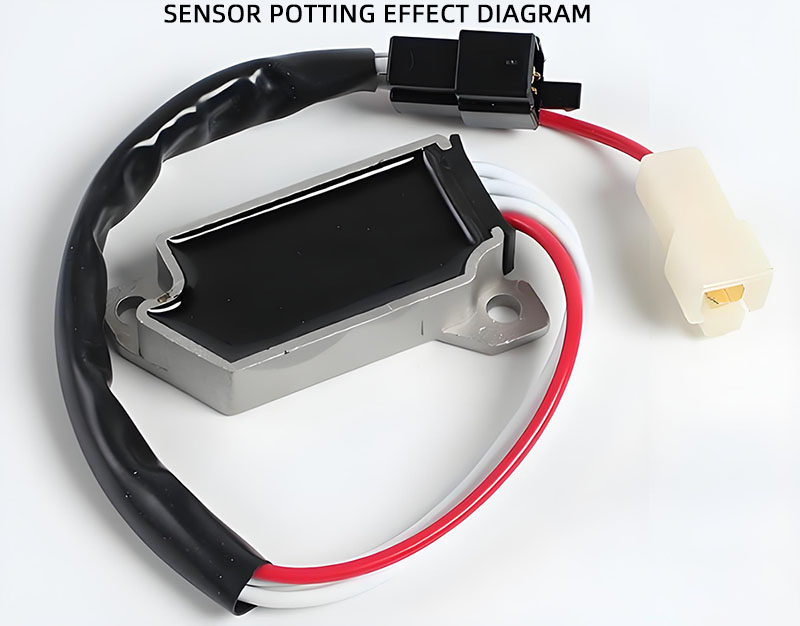

In modern electronics, especially in sensor manufacturing, environmental protection is critical to ensure long-term performance and reliability. One of the most effective methods to achieve this is epoxy potting, a process where sensitive electronic components are encased in a protective resin compound.

This article explores an advanced sensor epoxy potting solution that offers three key features:

Transparent encapsulation

High-temperature resistance

Flame-retardant properties

Whether you're designing automotive sensors, industrial monitoring devices, or IoT-enabled smart systems, selecting the right potting material can make all the difference in durability, functionality, and safety.

Epoxy potting involves filling a housing or casing around electronic components with a two-part epoxy resin system. Once cured, the epoxy forms a rigid or semi-rigid protective barrier that shields the internal circuitry from:

Moisture

Dust

Vibration

Thermal stress

Mechanical shock

For sensors, which often operate in harsh environments such as engine compartments, outdoor installations, or industrial machinery, epoxy potting provides essential mechanical support and electrical insulation.

Many modern sensors, especially those used in optical detection or fiber optics, require visibility through the potting material. A transparent epoxy potting solution allows engineers to inspect internal components without disassembly and supports the function of light-sensitive elements.

Clarity and UV stability ensure long-term visual access.

Maintains signal integrity in photodiodes and LEDs.

Reduces maintenance time due to easier diagnostics.

Sensors used in industries like automotive, aerospace, and energy must endure extreme temperatures. A high-performance epoxy potting compound should be able to withstand:

Continuous operating temperatures up to +180°C

Short-term exposure to over +200°C

Thermal cycling without cracking or delamination

Such materials maintain their structural integrity even under thermal expansion and contraction stresses, ensuring long-term operational stability.

Fire safety is a top priority in many applications, especially in enclosed spaces like electric vehicles, data centers, and industrial control cabinets. A quality epoxy potting compound should meet recognized fire safety standards such as:

UL94 V-0 rating (highest level of flame retardancy)

Low smoke emission

Non-toxic combustion byproducts

These properties not only protect the device but also contribute to overall system safety and regulatory compliance.

The versatility and protective qualities of epoxy potting make it ideal for a wide range of sensor types and industries:

Engine control unit (ECU) sensors

Oxygen sensors

Transmission and ABS sensors

Battery management systems in EVs

Pressure transducers

Temperature sensors

Proximity sensors

Vibration monitors

Wireless sensors in IIoT (Industrial Internet of Things)

Humidity and gas sensors

Edge computing modules

Power modules

Control boards

LED driver circuits

Selecting the appropriate epoxy potting material requires careful evaluation based on several criteria:

| Criteria | Consideration |

|---|---|

| Curing Time | Fast vs. slow curing depending on production line speed |

| Viscosity | Low viscosity for complex geometries; high viscosity for gap filling |

| Thermal Conductivity | Required for heat dissipation in power sensors |

| Mechanical Properties | Flexibility vs. rigidity based on vibration levels |

| Adhesion | Must bond well with substrates like PCBs, metals, and plastics |

| Regulatory Compliance | RoHS, REACH, UL, ISO certifications |

Consulting with material suppliers and performing sample testing is highly recommended before large-scale implementation.

Ensure the PCB and housing are clean and free of oils, dust, and moisture. Use isopropyl alcohol or plasma cleaning if necessary.

Most potting epoxies come in a two-component (A+B) format. Mix them thoroughly according to the manufacturer’s instructions—typically a 1:1 or 3:1 or 5:1 ratio.

To eliminate air bubbles, place the mixed epoxy in a vacuum chamber or use a low-speed mixer with degassing function.

Carefully pour the mixture into the sensor housing, ensuring full coverage without damaging delicate components.

Allow the epoxy to cure at room temperature or accelerate the process using controlled heat. Curing times vary from several hours to 24–72 hours depending on the formulation.

Perform electrical continuity tests, insulation resistance checks, and visual inspections post-curing to ensure reliability.

While other potting materials like silicones and polyurethanes exist, epoxy resins offer unique advantages:

| Property | Epoxy | Silicone | Polyurethane |

|---|---|---|---|

| Heat Resistance | ✅ Excellent | Good | Fair |

| Transparency | ✅ Available | Limited | Limited |

| Adhesion | ✅ Strong | Moderate | Moderate |

| Cost | Affordable | Higher | Mid-range |

| Flame Retardancy | ✅ Can be formulated | Needs additives | Possible |

| Durability | ✅ Superior | Soft and flexible | Less rigid |

For sensor applications requiring robustness, clarity, and fire safety, epoxy remains the preferred choice.

Yes, some formulations may experience slight discoloration due to UV exposure. Choosing UV-stable or optically clear grades can mitigate this issue.

Acetone solvents can be used for corrosion removal, or the glue can be softened by heating and baking before being removed.

Yes, most modern flame-retardant epoxies are non-halogenated and designed to minimize toxic emissions during combustion.

Typically between 6 months to 1 year when stored properly in sealed containers at room temperature.

In summary, a high-quality sensor epoxy potting solution with transparency, high-temperature resistance, and flame-retardant properties is essential for ensuring the longevity, performance, and safety of today’s advanced electronic systems.

By choosing the right potting compound and following best practices in application and curing, manufacturers can significantly enhance product reliability and reduce field failures—ultimately leading to higher customer satisfaction and lower maintenance costs.

Whether you’re working on next-gen automotive sensors or industrial IoT devices, investing in the right epoxy potting technology is a decision that pays dividends across the entire product lifecycle.