Epoxy Resin vs. Epoxy Glue: What Are the···

How Fast Does Epoxy Resin Dry? Factors T···

Epoxy Table Top for First-Timers: Tools,···

What is the Coverage Area of 1 Gallon of···

Heat-resistant thermal potting adhesive is a thermal management material specially designed for high temperature environments. It is usually composed of two components (component A and component B), which are solidified into a solid material by a chemical reaction after mixing.This potting adh...

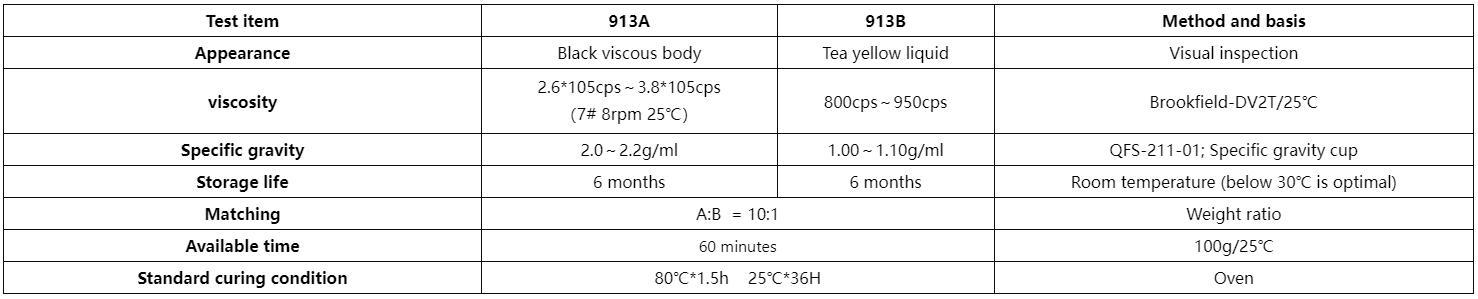

Basic parameters

Color:

proportions: 10:1

Curing time: 80℃*1.5h 25℃*36H

Temperature resistance range: -40-150℃ Cycle 1000 hours

Product TDS:

Application scope: Motor potting, new energy potting, electronic parts potting, etc

Product Description

Heat-resistant thermal potting adhesive is a thermal management material specially designed for high temperature environments. It is usually composed of two components (component A and component B), which are solidified into a solid material by a chemical reaction after mixing.

This potting adhesive has excellent thermal conductivity and high temperature resistance, and is suitable for thermal management and protection of various high power density electronic devices.

Main features:

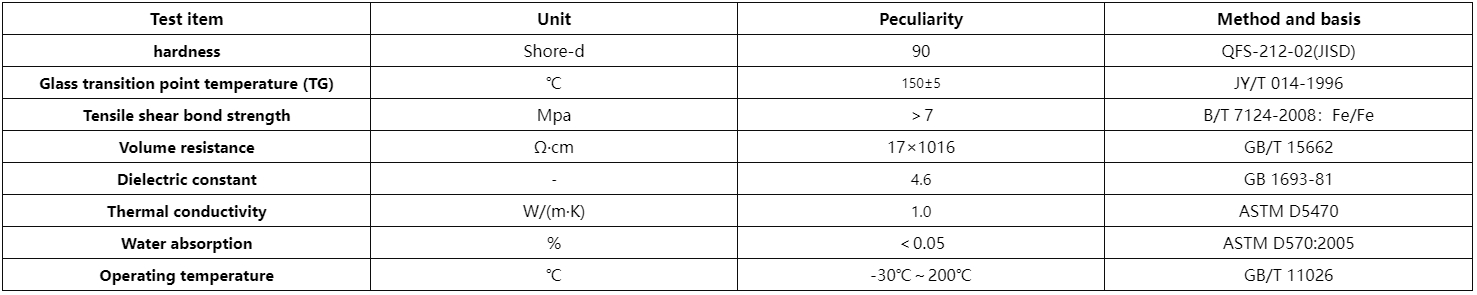

High thermal conductivity: The thermal conductivity is usually between 1.0 W/m·K and 2.0 W/m·K, which can effectively conduct heat.

High temperature resistance: Stable performance at 200°C or higher, suitable for extreme working environments.

Good fluidity: uncured potting glue has good fluidity and self-leveling, and is easy to fill small gaps.

Excellent electrical insulation: provides good electrical insulation performance to prevent short circuit and leakage.

Low stress: Cured potting adhesive has low internal stress, reducing the pressure on sensitive components.

Long service life: good aging resistance to ensure long-term and stable thermal conductivity.

uProduct features: before curing

----After curing

-The above data is the standard post-curing test state

Advantages of heat conduction potting adhesive

Efficient Thermal management:

Heat-resistant thermal potting adhesive can significantly reduce the operating temperature of electronic equipment, extend its service life, and improve the reliability of the system.

The high thermal conductivity allows the heat to be quickly transmitted to the radiator, avoiding local overheating.

Excellent temperature resistance:

It can work for a long time at temperatures above 200°C and is suitable for high temperature environments such as automotive engine compartments and industrial control equipment.

It maintains stable physical and chemical properties even under extreme temperature changes.

Easy construction:

The mixing process is simple, just mix A and B components evenly according to the specified proportion.

The self-leveling feature eliminates the need for complex tools and techniques during construction, saving time and costs.

Multifunctional protection:

It not only provides efficient thermal management, but also has good electrical insulation and mechanical protection functions to provide comprehensive protection for electronic components.

Strong seismic and shock resistance, suitable for harsh working environment.

Environmentally friendly and non-toxic:

Most heat-resistant thermal potting adhesives are made of environmentally friendly materials, which meet international environmental standards such as RoHS and are friendly to the human body and the environment.

Common application scenarios

Automotive Electronics:

The electronic control unit (ECU), sensors and other critical components in the engine compartment need to operate reliably at high temperatures. Heat-resistant thermal potting adhesives effectively dissipate heat and provide mechanical protection to ensure the proper operation of these components.

Industrial control equipment:

The electronic components such as PLC and inverter in industrial control equipment are easy to fail in high temperature environment. The use of heat-resistant thermal potting adhesives ensures the stability and reliability of these devices under high load operation.

Power module:

Power devices such as MOSFET and IGBT in the power module will generate a lot of heat during operation. Heat-resistant thermal potting adhesives can help these devices dissipate heat quickly and improve the reliability and stability of the power module.

LED Lighting:

LED lamp beads will accumulate a lot of heat under long working hours, especially in outdoor or high temperature environments. Heat-resistant thermal potting adhesive can help the LED chip to dissipate heat quickly, extend the service life of the lamp, and maintain a stable light output.

New energy vehicles:

Key components such as power batteries and motor controllers of new energy vehicles require efficient thermal management solutions. Heat-resistant thermal potting adhesive can meet the heat dissipation requirements of these components under harsh conditions such as high temperature and vibration.

Communication equipment:

Integrated circuits in communication base stations, switches and other devices generate a lot of heat during high-speed data transmission. Heat-resistant thermal potting adhesives provide efficient thermal management solutions to ensure the normal operation of communication equipment.

Precautions for use

Accurate proportion:

When mixing group A and B, the ratio must be strictly in accordance with the proportion provided by the manufacturer, otherwise it will affect the curing effect and thermal conductivity.

Stir well:

During the mixing process, ensure that the two components are fully stirred evenly to avoid unreacted areas that affect the final performance.

Exhaust treatment:

Before potting, it is recommended to use a vacuum defroster to remove bubbles from the mixture to ensure that the surface after potting is smooth and free of pores.

Curing conditions:

According to the requirements of the product manual, the appropriate curing temperature and time are selected to ensure that the potting adhesive is fully cured and achieves the best performance.

Safety protection:

Wear appropriate personal protective equipment, such as gloves and goggles, during construction to avoid skin contact and inhalation of harmful substances.